Industry 4.0

What is Industry 4.0?

Industry 4.0 is a buzz word to many people, but what is it? Simply, Industry 4.0 is the next evaluation in manufacturing that uses enhanced data collection to increase machine throughout, prevent downtime by predictive maintenance and connect machines over a Time Sensitive network (TSN) with one another and create and share information that is stored in a secure cloud. Data is able to be analyzed in real time allowing businesses to increase profitability.

Industry 4.0 Benefits

- Machine Learning, predictive maintenance, less downtime

- A Reduction in Machine Down Time – Automating strategic maintenance schedules, has been proven to reduce maintenance time by 20-50%, while simultaneously decreasing associated maintenance costs by around 5-10%.

- Maintains Efficiency – Relying on analytical data to improve the efficiency of the machinery, means that unnecessary maintenance is no longer necessary. This means that the life cycle of the machinery is extended, and any issues uncovered by the technology can be scheduled for repair when the machine isn’t in use.

- Data driven decisions, increased visibility, improved efficiency – Investing in Industry 4.0 gives businesses better insight and control over their operations allowing collaboration between individual departments ensuring manufacturing processes are optimized for efficiency.

- Trim costs, boost profits, fuel growth – Industry 4.0 technology helps you manage and optimize all aspects of your manufacturing processes and supply chain. It gives you access to the real-time data and insights you need to make smarter, faster decisions about your business, which can ultimately boost the efficiency and profitability of your entire operation.

Giving Mind to Process

Our technical sales team is here to assist you from conception to production.

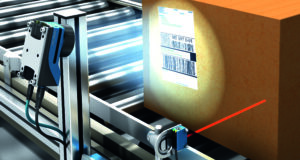

Industry 4.0 Solutions

Industry 4.0 Terminology

- IoT: IoT stands for Internet of Things, a concept that refers to connections between physical objects like sensors or machines and the Internet.

- IIoT: IIoT stands for the Industrial Internet of Things, a concept that refers to the connections between people, data, and machines as they relate to manufacturing.

- Artificial intelligence (AI): Artificial intelligence is a concept that refers to a computer’s ability to perform tasks and make decisions that would historically require some level of human intelligence.

- IO Link: Is point-to-point industrial communication networking standard (IEC 61131-9) used to exchange process data, value status data, device data and event data from sensors and actuators.

- M2M: This stands for machine-to-machine, and refers to the communication that happens between two separate machines through wireless or wired networks.

- Digitization: Digitization refers to the process of collecting and converting different types of information from analog outputs into a digital format.

- TSN: Is an update to the IEEE Ethernet standard that includes standard time synchronization and deterministic network communication over standard Ethernet.

- MES: A manufacturing execution system is an information system that connects monitors and controls data flows on the factory floor to improve production output.

- Smart factory: A smart factory is one that invests in and leverages Industry 4.0 technology, solutions, and approaches.

- Machine learning: Machine learning refers to the ability that computers have to learn and improve on their own through artificial intelligence—without being explicitly told or programmed to do so.

- Predictive Maintenance (PdM): By condition monitoring the performance and condition of equipment during normal operation, down time can be reduced by predicting the life cycle of equipment before it fails.

- Cloud computing: Cloud computing refers to the practice of using interconnected remote servers hosted on the Internet to store, manage, and process information.

- Real-time data processing: Real-time data processing refers to the abilities of computer systems and machines to continuously and automatically process data and provide real-time or near-time outputs and insights.